Number of attendees: 27

- Jim (President) opened the meeting at 7:30pm

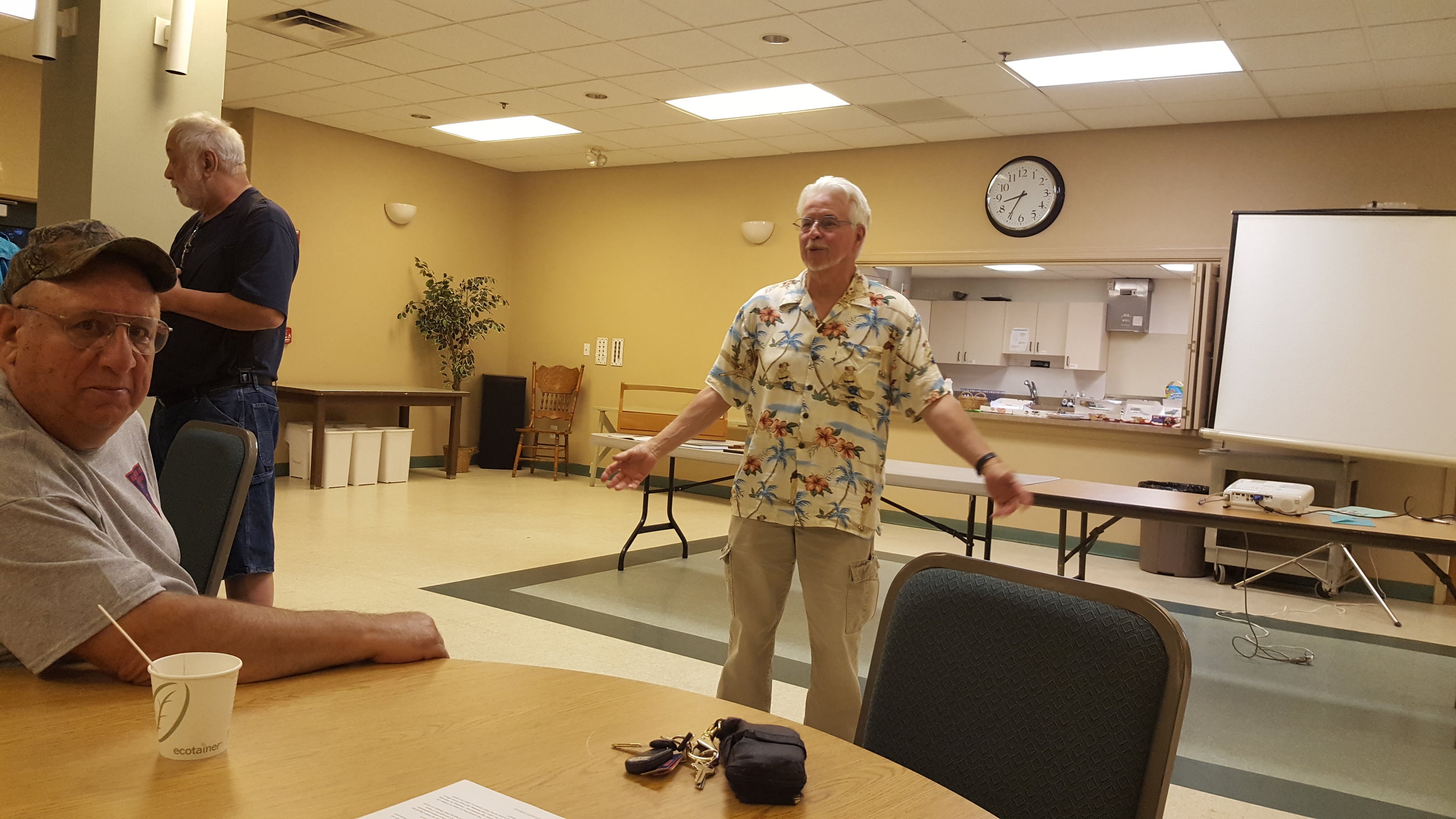

- Carl introduced David & Wade from Delaware Tool Exchange (pic 1)

- Two friends were looking for a way to get a business going

- Inherited some tools from fathers

- Grew, now in 1,300 sf building

- They work on consignment – you provide them tools, they sell, you get money, they take a cut

- Open Sat/Sun (they both have regular jobs)

- Invited the guild to come down and see what they’re selling, and talk with them

- You can call ahead and see if they have something you want, you can also give them a “wish list” and if your tool comes in, they will contact you

- Difficult for them to hold an item – they will sell it to who gets their first (only fair)

- They have shipped at times

- Close to Woodcraft store so you can shop at both

- Jim introduced some new People

- Jeff saw us on our website. Trying to do some woodworking, has a circular saw, drill, etc.

- Rosemary – inexperienced, wants furniture in her living room

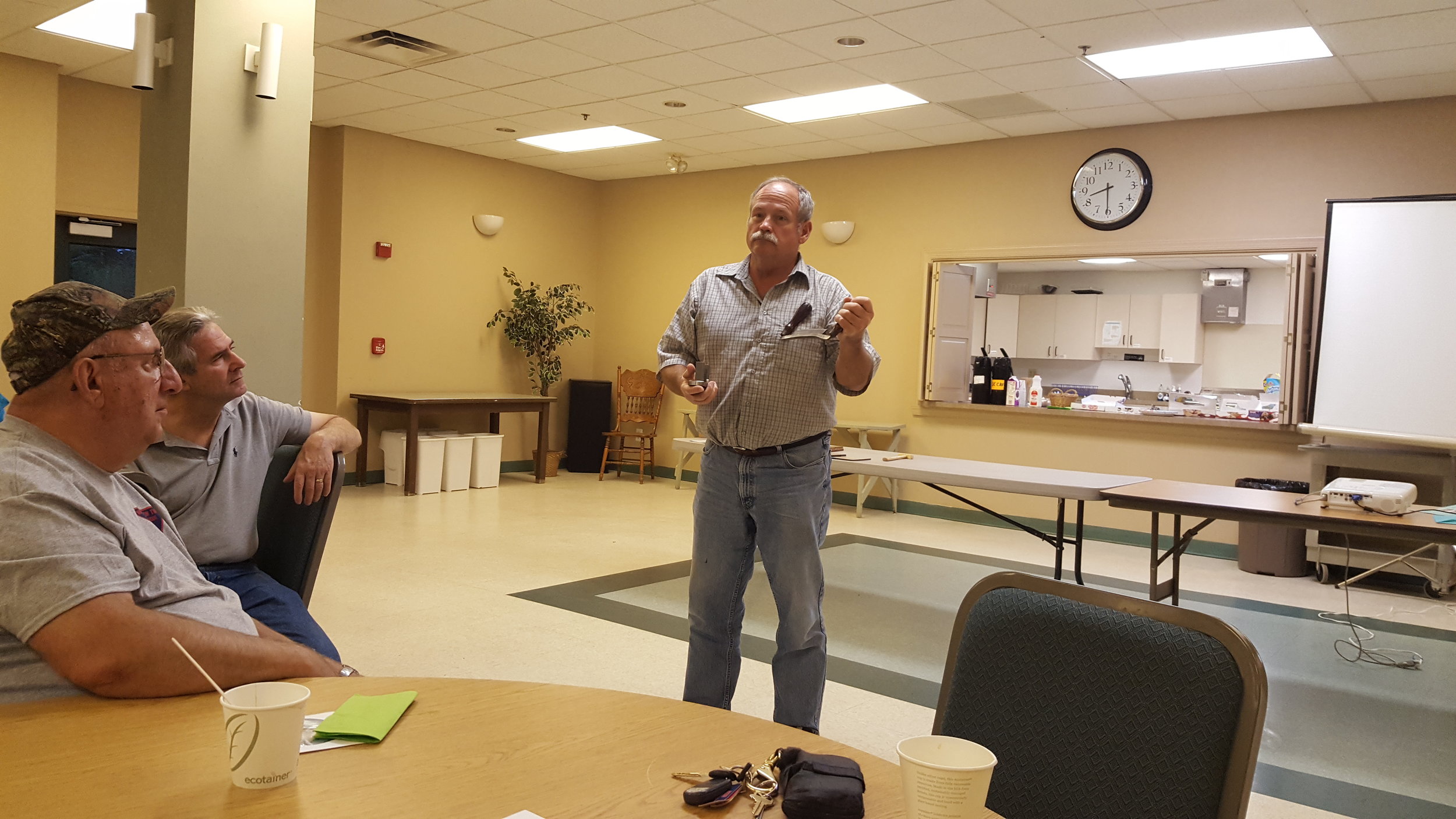

- Tom Calisario (pic 2)

- Director of Urban Boatworks, in existence since 2009 in Camden

- Small school, less than 200 kids from kindergarten to high school

- Talked about challenges and objectives of school (a lot of hands on classes)

- Used watercraft & boat building to teach other skills

- Working on a lot of shop skills & tech skills for them (woodworking, welding, pipe fitting, etc.)

- Used “stitch & glue” technique to build, and then fiberglass & epoxy

- A lot of discussion on techniques, safety, and kids

- Demo on putting on fiberglass & epoxy

- Further information is located at http://urbanpromiseusa.org/boatworks

- He asked folks to please come visit!

- Dave Potts (Finance): Two expenditures leaving $3,854.49 in account

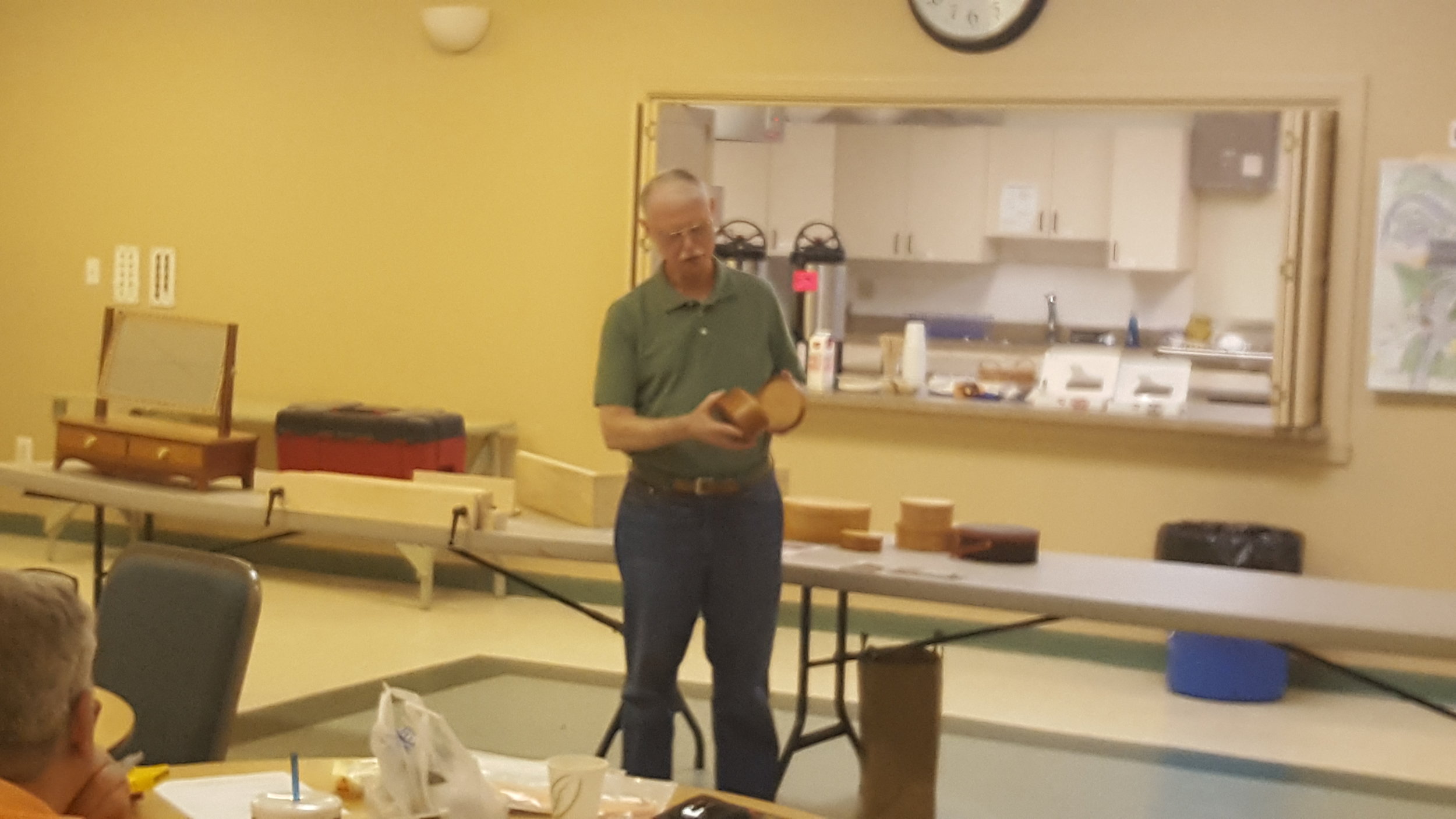

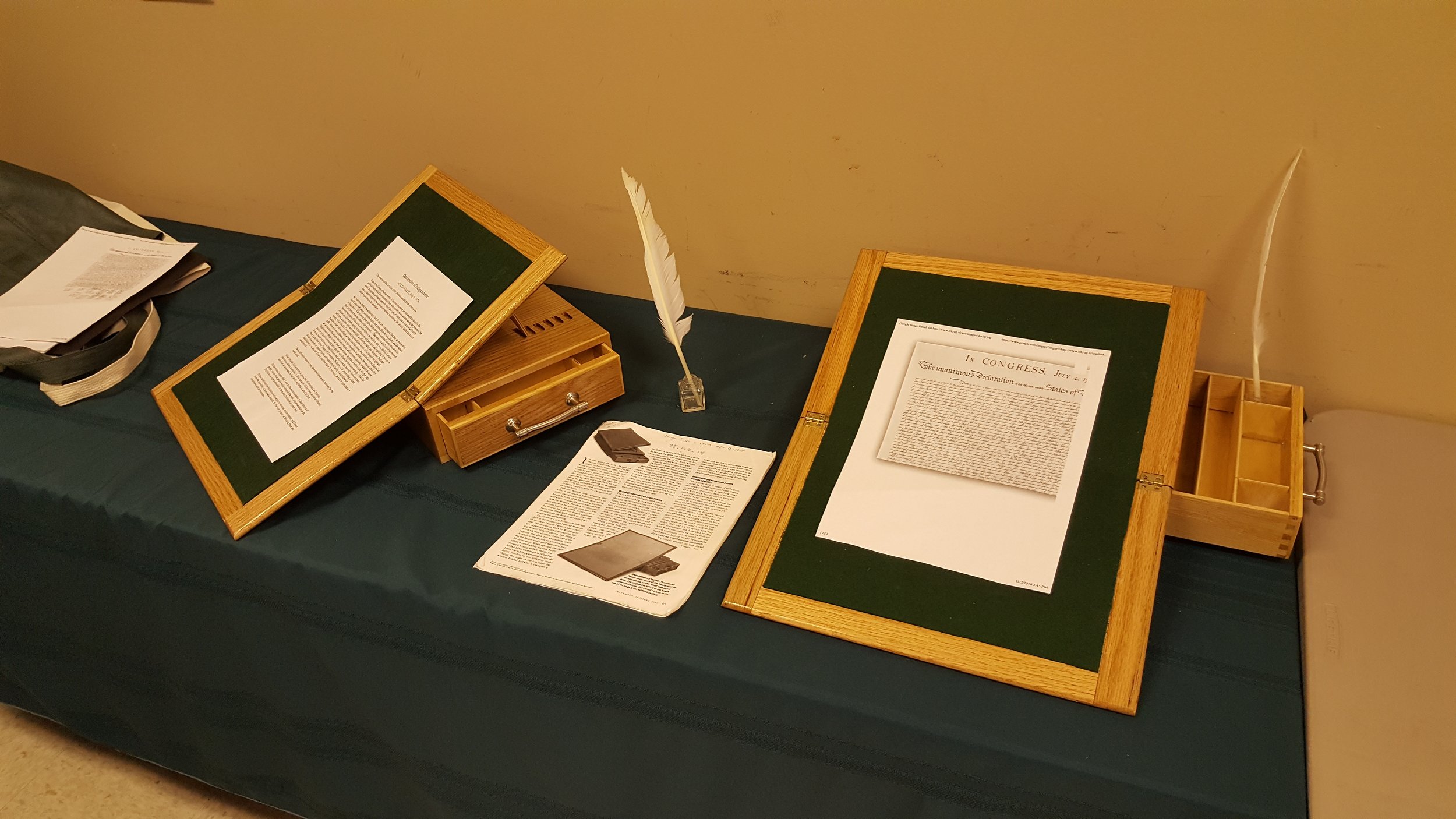

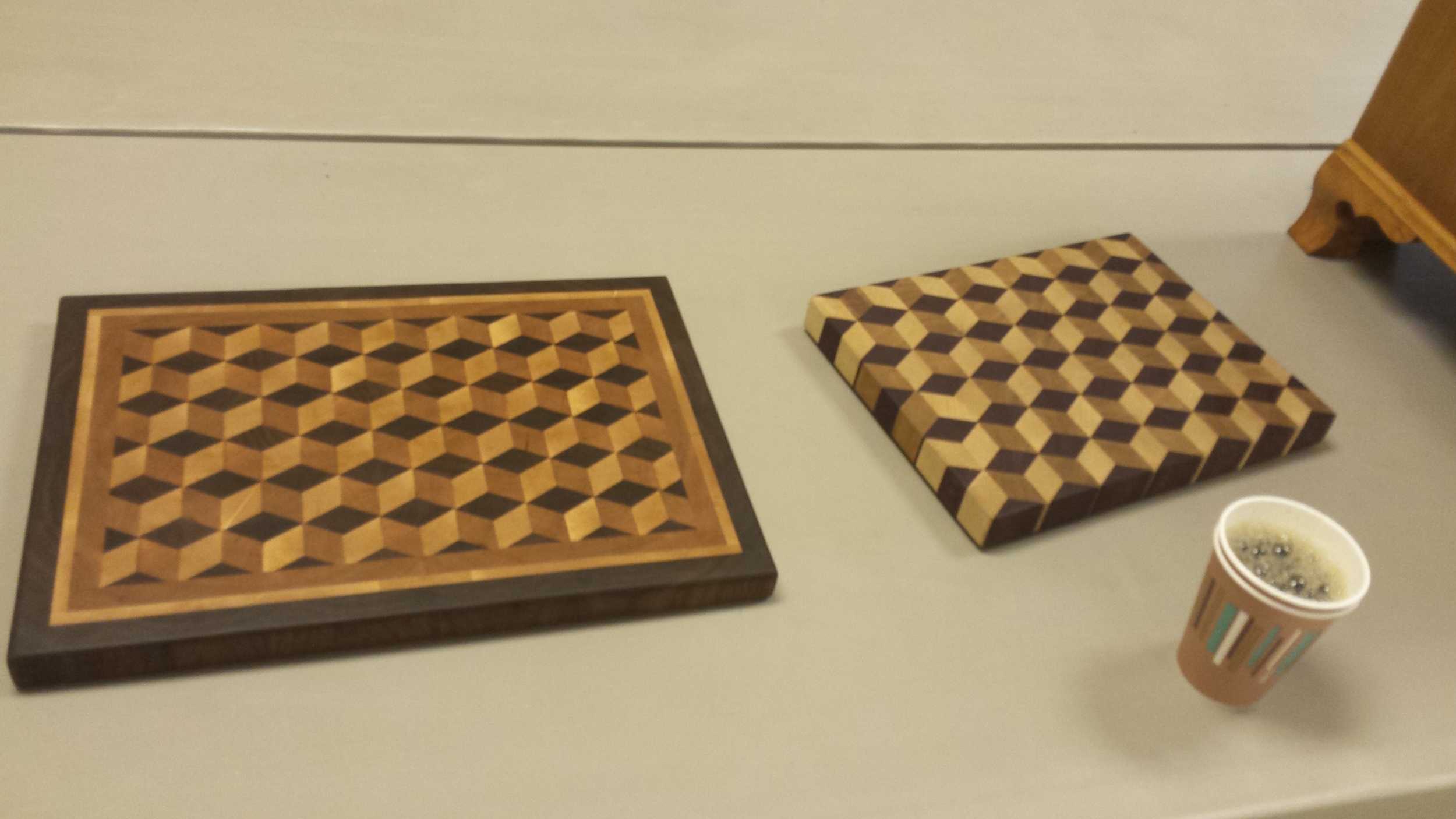

- Salman asked guild earlier about clear glue, got ideas from guild members, so he made a chessboard(pic 3)

- Provided example of using clear glue (from idea guild member provided).

- The glue was very viscous (like glycerin). Aleene's Original Clear Gel Tacky Glue.

- Scroll sawed a lot of pieces

- Salman also talked about his inkjet printer that lets you print on PVC cards. He can make a batch for anyone, $30 for a card

- Salman asked if anyone uses software to create cut lists. He found an online paper written by some Iranian PhDs who described a software system to make guillotine cuts efficiently. Minimized costs, cuts, etc.

- Available on http://wgsj.org/cutlist-generator

- John provided examples of spoons, spatulas and other items that he carved (pic 4)

- Plan is to make Christmas gifts for everyone

- Based on watching Paul Sellers

- Used machines to get basic form, then carved by hand

- Used Maple

- Mark built a workbench for the Guild (pic 5)

- Bench has cabinet below (for storage stuff)

- Idea is for it to live here in the church's basement

- Entire Guild was very impressed

- It was built to be used, but also to sit to the side when not in use and to look nice for the church when resting to the side

- He’ll go over it in more detail in next month’s meeting

- Mike talked about plans for the church to put wainscoting around the columns for the church basement. He is looking for volunteers to help on a Sat & Sun in October

- Next meeting is scheduled for Thursday, Oct 5th at 7:15pm. Mark will go over his workbench and Mike has another speaker

- Meeting concluded at 9:35pm