Total number of attendees: 14

- Jim (President) opened the meeting at 7:41pm

- Dave Potts (Finance)

- $4,370.49 in treasury

- Jim Parise spoke about Center for Art in Wood (Philadelphia, PA)

- Jim was less than impressed with Center for Art in Wood, in terms of woodworking

- A lot of turned items or “mangle boards”

- The demo on coopering was not very impressive. He arranged items/sculpted items, but the barrel was really just decorative

- Lathe work was good

- Whiskey was very good

- Parking was ample

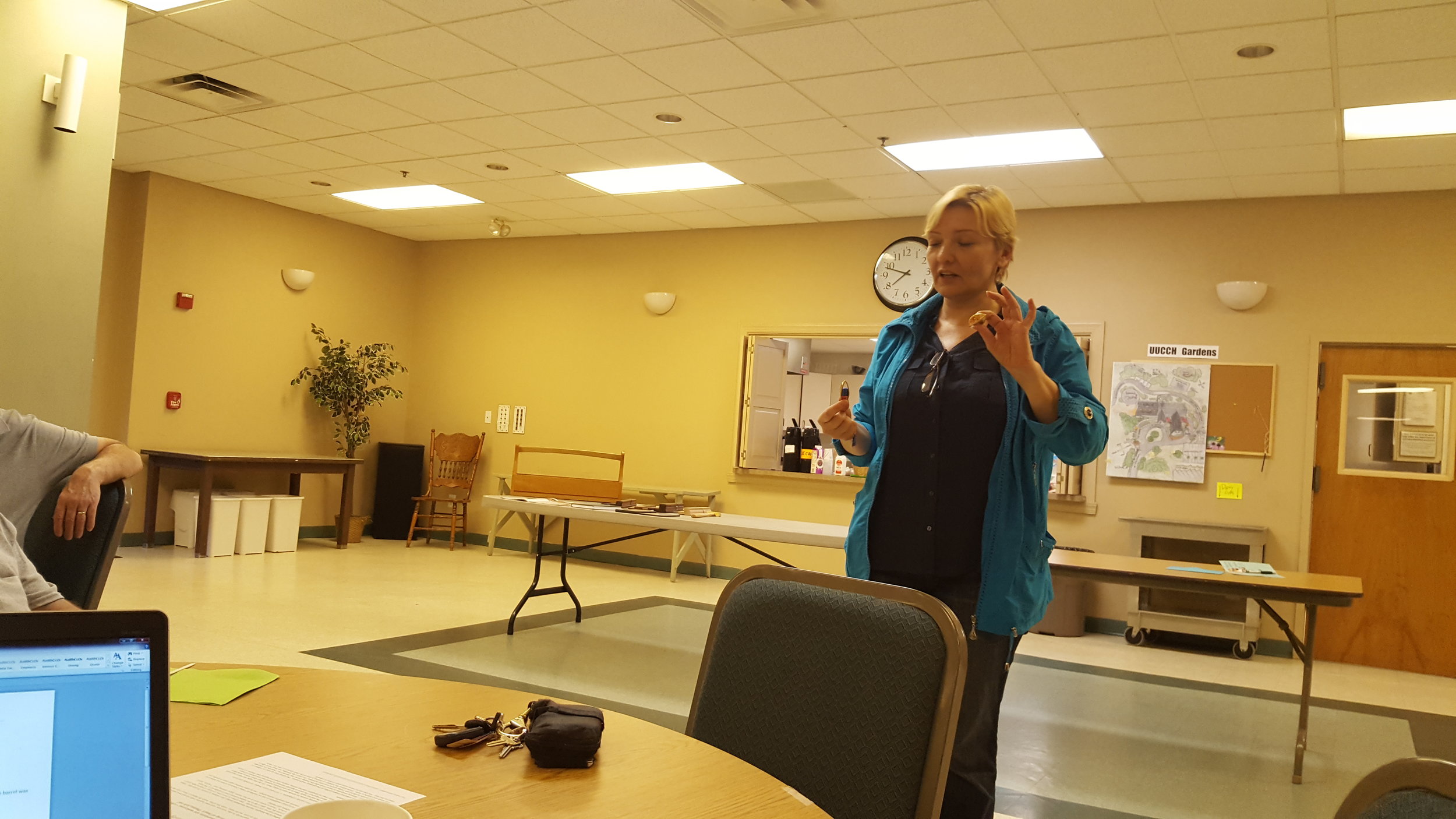

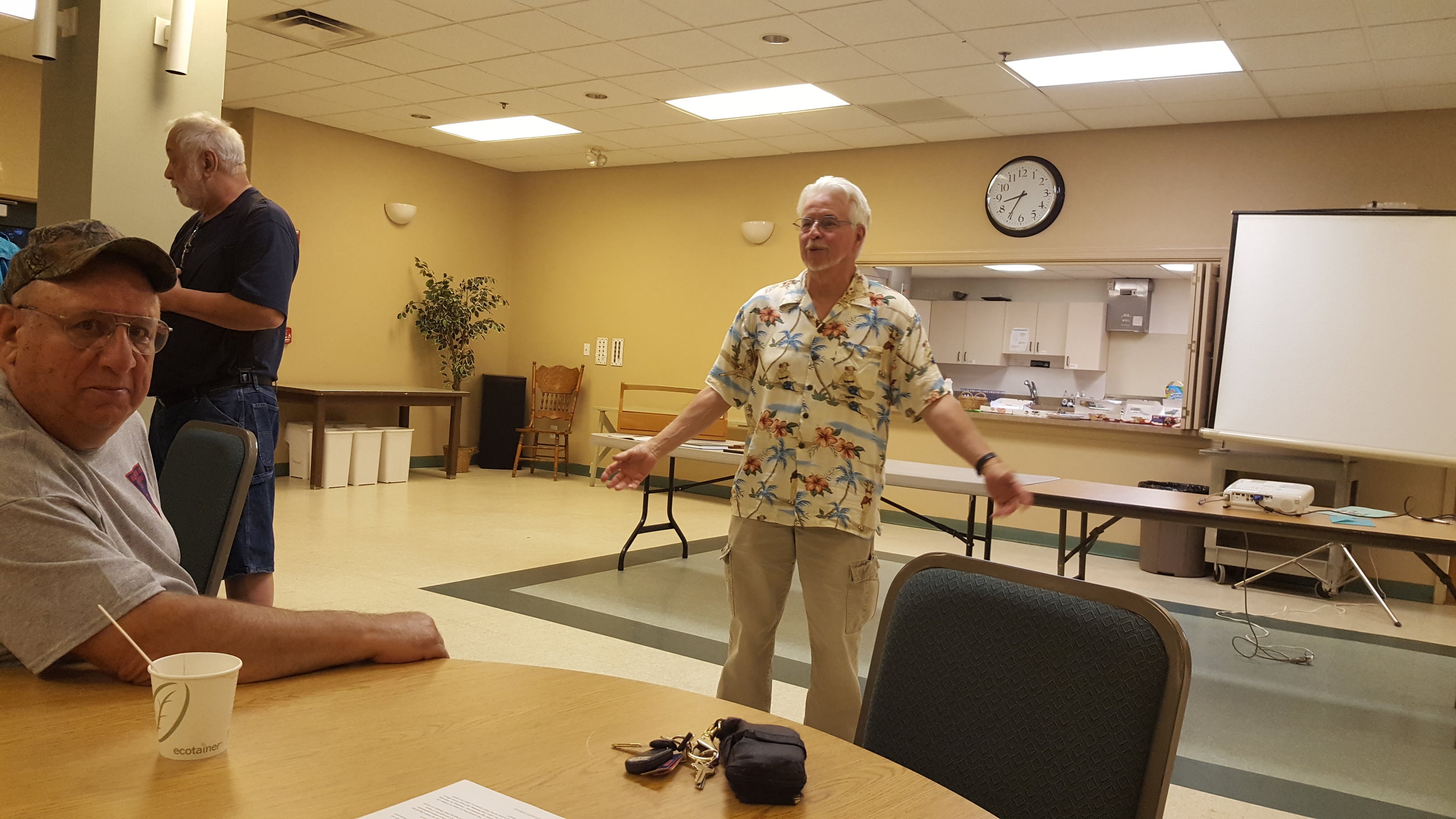

- Rita gave a presentation on wood tool for making lace (Pic 1 & 2)

- Art teacher in Russia before she came here

- Introduced to lace making guild – they had problem finding good tools

- She had woodworking knowledge from her grandfather

- Shell inlays, made of veneer

- Steam & glue together

- Bend them with clamps

- Take carving knife and carve inlay on it

- Struggling with finishing the tools

- General discussion on ways to do build process by group

- Suggestion was made to use TransTint aniline dye

- Art talked about Hearne Hardwood in Oxford PA (southwest of Philadelphia) (pic 3)

- Open house Sep 29th & 30th

- Big bandsaw will run (the one they bought from the US Navy yard)

- Lots of wood species to buy

- Contact Jim if you’d like to carpool

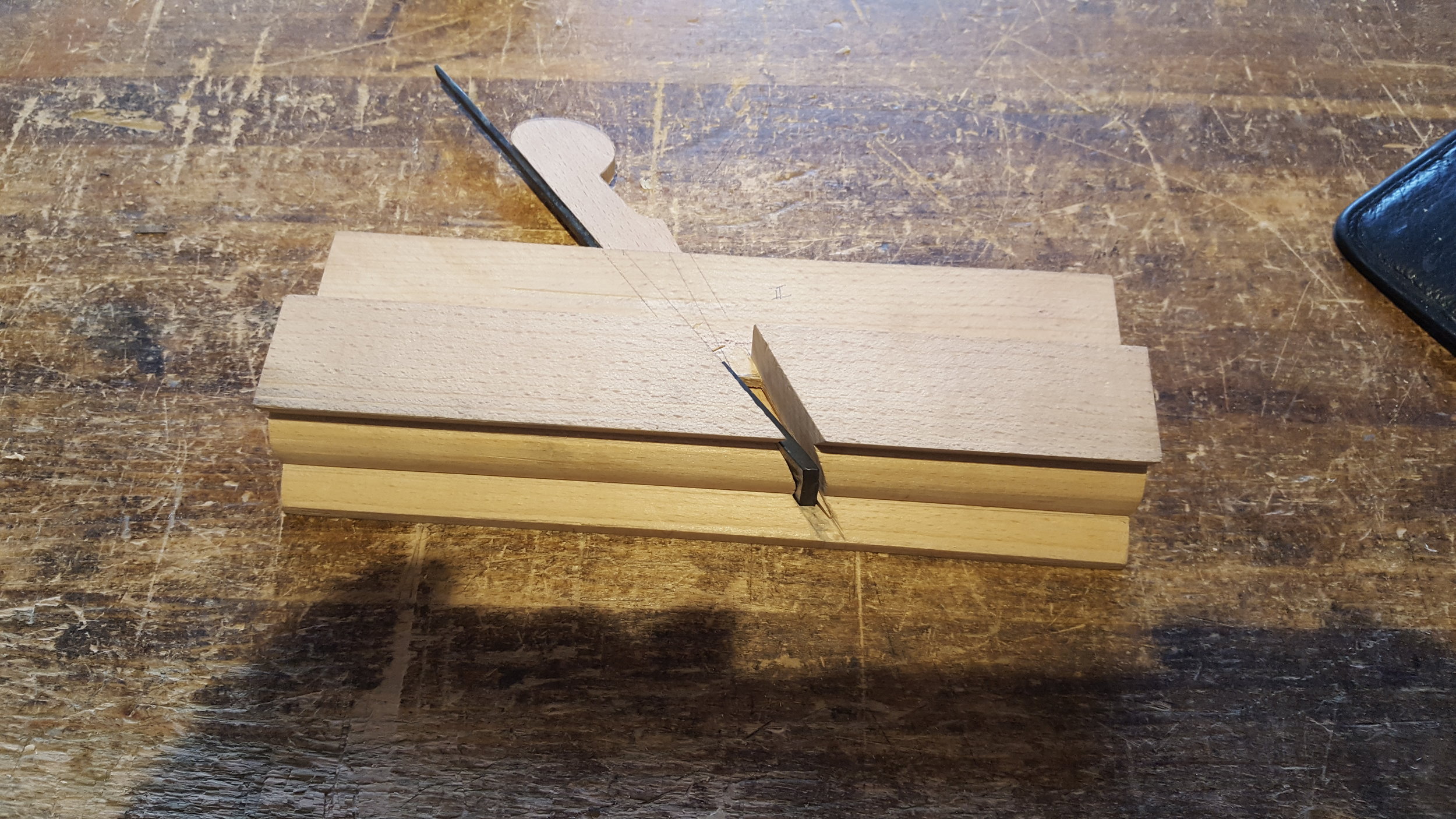

- Kevin showed pictures of his training class at the Woodwright’s School in Pittsboro NC (pic 4)

- School is in Pittsboro NC (near Raleigh)

- Class was 3 days, and you learned to take beech blank and make a fully functional molding plane (Kevin made a cove plane)

- First 2 days you are shaping the plane (cutting profile & scraping it to shape, cutting mortise, shaping the wedge, refining it)

- Day 3 you are tempering, shaping and hardening the iron, before sharpening it

- By end, you are cutting profiles in wood trim with your new plane

- Excellent experience. You could come away from the class and start making multiple molding planes as you move forward on it

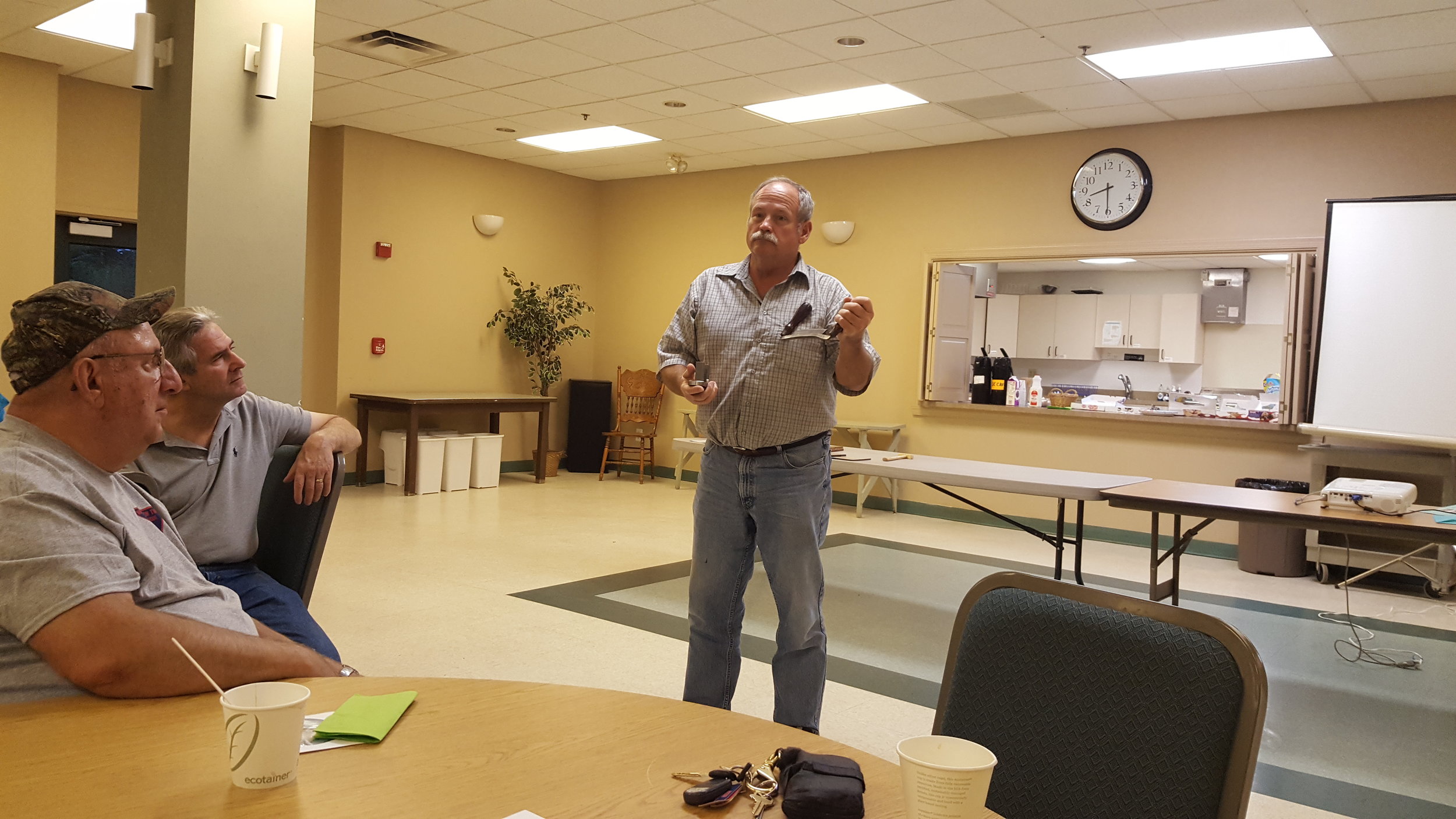

- Mark talked about sharpening of draw knife (pic 5)

- Jig was created to sharpen one side, back & forth

- Second edge of jig cuts the exact angle you need on the one side

- Variety of diamond and sand paper sharpening edges

- Benchmade is making them, based on Galbreth’s design

- Jim was asking for folks to do demo on sharpening scrapers

- Tom Calistereo will bring boat and do presentation for class (25 ft canoe)

- Next meeting is scheduled for Thursday, July 6th at 7:15pm

- Meeting concluded at 8:43pm