Total # of Attendees: 22

- Mike opened the meeting at 7:26pm. He was not recognized by the guild body

- Treasurer (Dave) was taking membership dues - $50

- Brian Menold’s wife (Pete’s Sister) passed away last week, and Jim passed around a card, as well as a a bowl to contribute towards a tree in honor of Brian’s wife

- Feb 8 & 9 (Fri & Sat) at Independence Seaport Museum, Lie Nielsen event in Philadelphia. Museum is worth the trip by itself. You can also pay $8 to visit the Olympia & the sub. Parking around $16 - $20

- Visitors:

- Scott visited in fall. Woodworker his whole life

- Matthew from Philadelphia, mostly hand tool work (boats, instruments, etc.) Originally from Canada

- Andy Dick, woodworker want-to-be, semi-retired, time on hand. Built stuff in back (cradles, bookcases, etc.)

- Bob Mathis, Pitman, retired teacher, working on wood for some time

- John, here with Scott. Retired now, trying to get reacquainted with his tools

- Matthew did a 17th century style chest, Quarter-riven oak, did some carvings around it. No glue on joints, its nailed, used planes he made to make the molding on side. Has done a lot of carving. With green wood, it comes off real fast. Each panel in about 45 minutes. Forged nails

- Mar 2 & 3rd for Woodworking Show in Secaucus NJ. Jim is driving up with folks

- Jim showed his band saw box. Glued it up, cut bottom off, clean out inside, then glue bottom back on (and wait for glue to dry). Great Valentine’s Day gift.

- The group discussed, talked about sources for inspiration like the website http://lumberjocks.com

- Introduced our guest instructor, Dave Potts

- Dave showed off banding, stringing and sand shading

- Banding can be cutting off little tiny squares from length (used band saw & regular fence)

- Discussion of other ways to do banding (45 degree cuts on band saw, etc.)

- To layout out, use a square and sharp knife to cut line, then laid banding on the line & put knife on other side. Remove banding, put square to knife, then use knife to finalize cut

- Use small router plane to rout out shallow depth in a controlled way, and then lay in banding.

- Banding can be slightly “proud” and then sanded down – but not too much (you don’t want to dig in)

- Stringing – he uses maple or for a white line.

- He often uses a band saw or table saw to cut it, even though it’s thin.

- Uses templates to help cut the string. Uses rotary tool (suchc as Dremel) to ride along template to cut for it, then inserts the stringing (1/32”) into place

- Uses a lot of mini-drill bits to make the cuts

- Make sure you go slow as you cut. If you go too fast, it may snap bit or burn out the wood.

- Uses Blue Spruce bits

- Uses simple jig (block of wood, band saw blade, screws) to scrap bottom and put small “V” in it, to assist it in getting into the groove

- Sand shading – used to help bring additional color to inlay

- Used curved gouge to make oval shape, partially dug out a ready to be put in

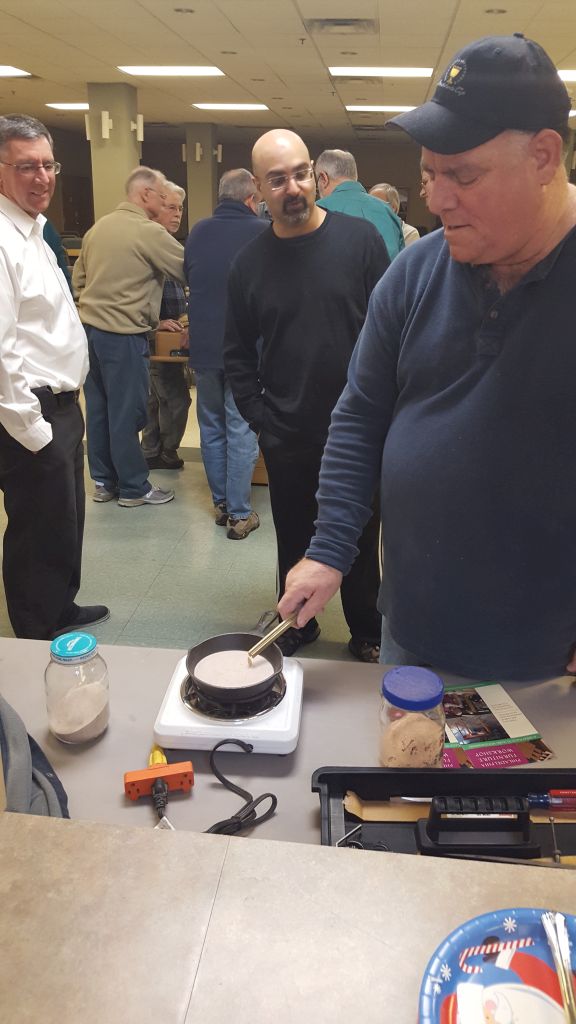

- Heat up sand in griddle, stick piece in, and use that to change the color of the wood

- Cleaned out, then used same gouge to cut overlay leaf, glued it up, and then placed it in

- Next Meeting on Thursday, March 1st at 7:30pm. Salman will be showing off scroll saw skills and work

- Meeting concluded at 9:02pm.